Choosing the Right Membrane Switch for Your Business Needs

Choosing the Right Membrane Switch for Your Business Needs

Blog Article

The Advantages of Making Use Of Membrane Switches Over in Consumer Electronics

Membrane layer buttons are increasingly recognized for their considerable benefits in customer electronic devices, especially in boosting customer communication and streamlining production processes. The flexibility in style enables for customized options that fulfill varied customer demands.

Boosted Customer Experience

In today's competitive landscape of customer electronic devices, boosted individual experience is extremely important; virtually 85% of individuals focus on user-friendly interfaces. Membrane switches over play an essential role in achieving this level of use. Their level, inconspicuous style enables for seamless integration right into different gadgets, decreasing mass while keeping capability. This layout visual not only enhances the aesthetic charm however also adds to a more streamlined individual interaction.

The tactile feedback provided by membrane switches is crucial for directing customer actions, guaranteeing that commands are registered properly. This feedback device heightens and lessens errors individual satisfaction, cultivating a favorable relationship between the user and the device. The customizable nature of membrane layer switches over permits suppliers to tailor user interfaces to certain individual demands, making gadgets more accessible and inviting.

Additionally, membrane layer buttons can include backlighting and visuals overlays, better enhancing presence and functionality in varied settings. This versatility guarantees that tools remain useful and straightforward, no matter the setting. Overall, the assimilation of membrane layer switches over into customer electronics dramatically enhances user experience, driving brand loyalty and contentment in an increasingly open market.

Economical Manufacturing

Consumer electronic devices manufacturers are frequently looking for ways to balance top quality with affordability, and membrane buttons offer an engaging solution for economical manufacturing. These parts are naturally easier than conventional mechanical switches, which reduces both production prices and complexity. The lightweight layout of membrane layer changes enables lower shipping expenditures and much easier assimilation right into portable devices, further improving their allure in an affordable market.

Suppliers can create membrane layer switches in high volumes, benefiting from economic climates of range. This mass production capacity makes sure regular top quality while significantly reducing per-unit prices. Additionally, the products used in membrane switches, such as polyester and polycarbonate, are commonly less costly than those needed for standard button modern technologies, contributing to general cost savings.

The manufacturing procedure for membrane switches usually requires less steps and less labor compared to various other button types. This structured technique not just reduces labor expenses yet likewise accelerates time-to-market, enabling firms to react quickly to consumer need. Subsequently, the combination of lowered product expenses and efficient manufacturing procedures settings membrane layer changes as a smart financial investment for makers aiming to deliver high-quality customer electronic devices at affordable price points.

Layout Flexibility and Customization

While typical mechanical switches usually impose limitations on layout because of their bulk and needed installing mechanisms, membrane buttons give unequaled flexibility and personalization alternatives for customer electronics. This cutting-edge technology permits developers to produce streamlined, low-profile interfaces that can perfectly integrate into various More hints product aesthetic appeals, from mobile phones to kitchen area home appliances.

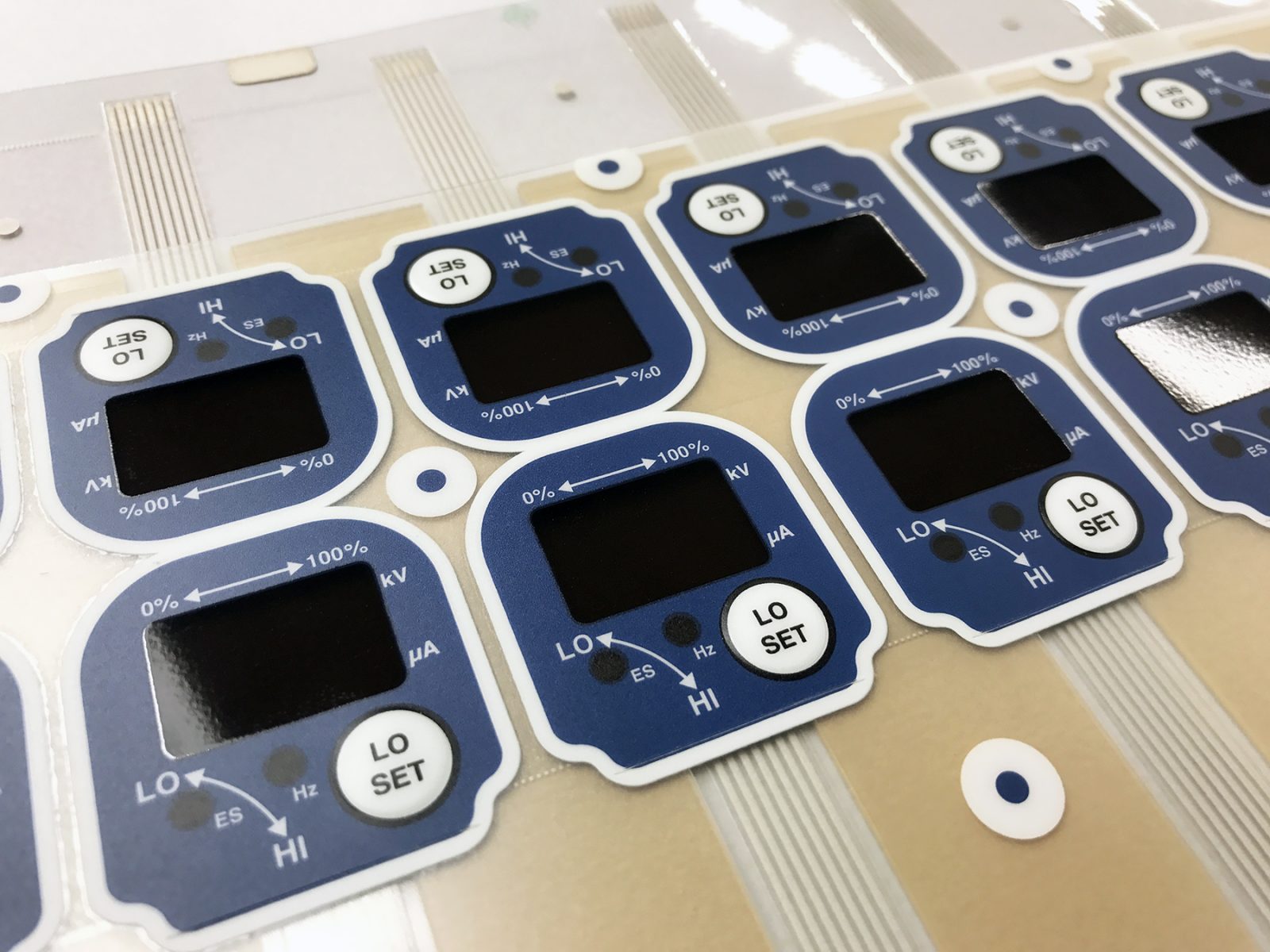

Membrane buttons can be created in practically any kind of form or dimension, enabling suppliers to customize the design to specific ergonomic and useful needs. This versatility not only boosts individual experience but also allows for creative layouts that straighten with brand identity. The use of published graphics on membrane switches offers the chance for detailed designs and dynamic shades, which can be easily modified without considerable cost implications.

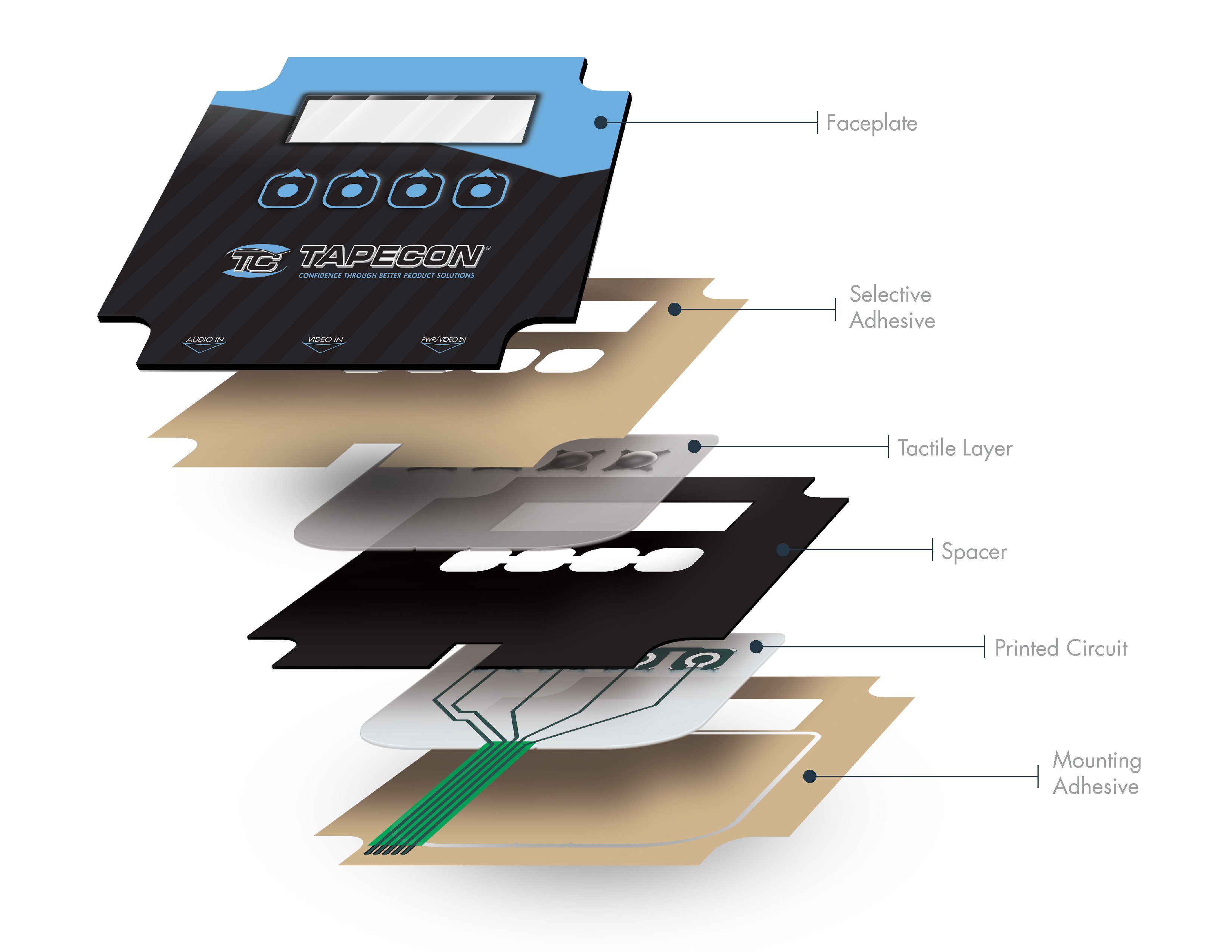

Furthermore, membrane buttons can integrate several capabilities right into a single layer, reducing the need for several components and simplifying setting up processes. This structured style method decreases space and weight, making it perfect for small consumer electronics. Generally, the style adaptability and customization capabilities of membrane layer switches over empower producers to innovate, inevitably bring about even more interesting and easy to use products.

Durability and Dependability

As technology continues to develop, the resilience and reliability of membrane buttons have actually come to be crucial considerations for suppliers in the consumer electronic devices sector (membrane switch). Membrane layer buttons are made to endure harsh environmental problems, consisting of temperature variations, moisture, and dust exposure. Their robust building usually includes multi-layered products that supply an effective obstacle against contaminants, ensuring durability and constant efficiency

Additionally, membrane buttons can withstand a considerable variety of actuations without loss of functionality, commonly going beyond millions of cycles. This toughness equates to decrease replacement expenses and lowered downtime for manufacturers and consumers alike. Generally, the combination of environmental strength and mechanical dependability makes membrane layer changes a calculated option for consumer electronic devices, guaranteeing that devices remain functional and reliable throughout their desired life-span.

Streamlined Item Advancement

The sturdiness and dependability of membrane changes dramatically contribute to structured product growth in the customer electronic devices field. By integrating these switches early in the design procedure, manufacturers can lower the intricacy and variety of components required in their products (membrane switch). Membrane switches are light-weight and portable, enabling for extra efficient space utilization within devices, which can result in streamlined assembly procedures

Additionally, the modification capabilities of membrane buttons enable designers to tailor functions particularly to customer requirements without sustaining extreme expenses or hold-ups. This flexibility promotes innovation, as firms can swiftly iterate styles based on market here are the findings responses, ultimately accelerating the time-to-market for new items.

The ease of manufacturing membrane layer switches also plays an essential role in item growth. With modern-day printing methods see and materials, manufacturing can be scaled effectively, minimizing and reducing lead times waste. This causes reduced production prices, enhancing total productivity.

Verdict

In final thought, membrane switches over considerably boost customer electronic devices by supplying an enhanced customer experience, economical production processes, and versatile layout choices. The combination of membrane layer switches stands for a calculated option for suppliers looking for to optimize item style and performance.

Membrane buttons are increasingly acknowledged for their substantial benefits in customer electronic devices, specifically in improving user communication and improving production processes. Additionally, the materials made use of in membrane layer switches, such as polyester and polycarbonate, are usually less pricey than those needed for conventional button modern technologies, contributing to general price savings.

The production process for membrane layer switches over usually needs fewer actions and less labor contrasted to various other button types. Unlike conventional mechanical switches, which might wear out over time, membrane layer changes utilize a closed design that decreases the danger of mechanical failing.In final thought, membrane switches dramatically improve customer electronics by giving an enhanced customer experience, economical manufacturing processes, and functional style alternatives.

Report this page